Driving innovation: how our digital twin initiative with NVIDIA and SoftServe enhances material handling

Warehouse Automation

Information

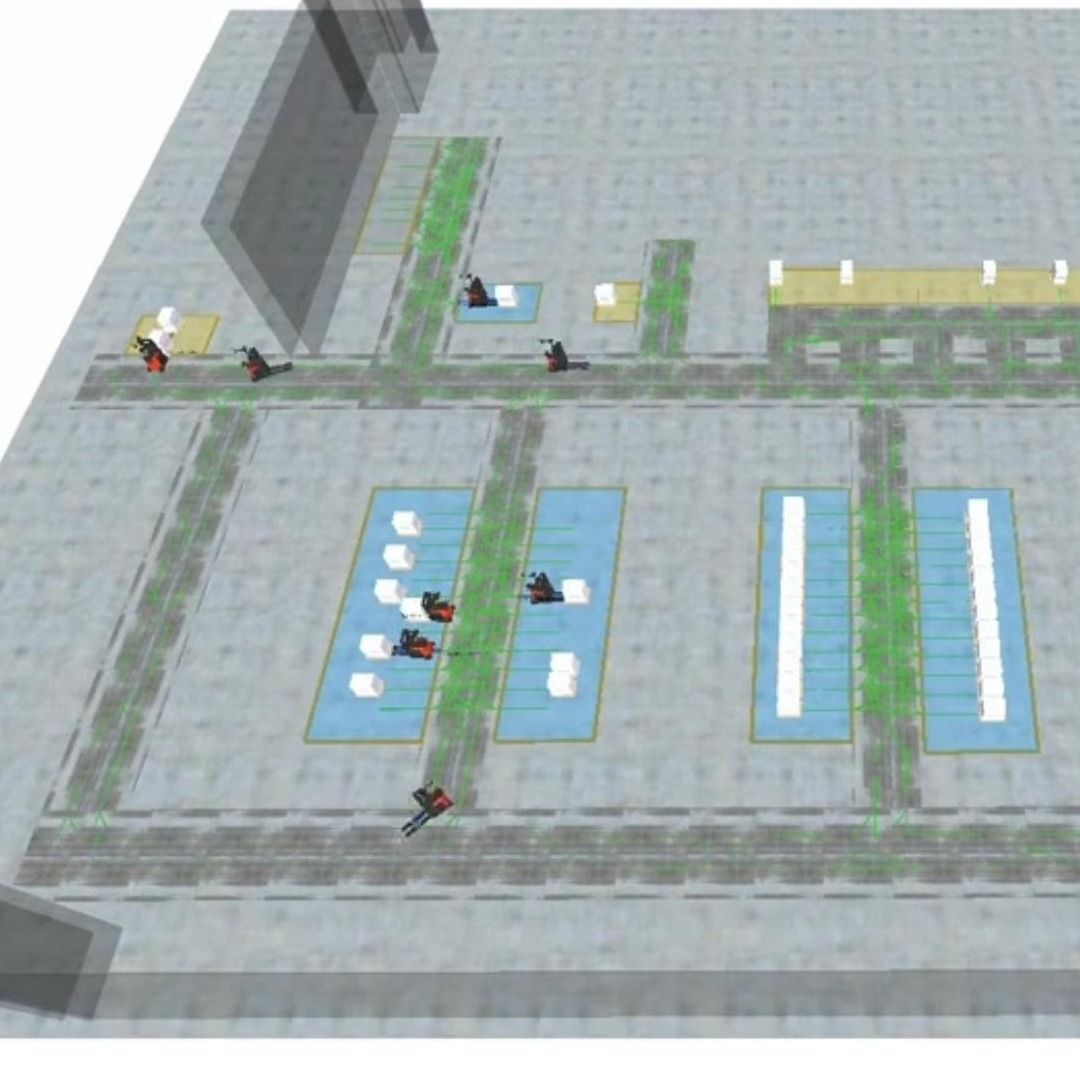

In the rapidly evolving world of robotics and automation, Toyota Material Handling Europe is taking bold steps to accelerate the speed of innovation and reduce Time-to-Market. In collaboration with NVIDIA and SoftServe – a premier IT consulting and digital services provider and global leader in Physical AI solutions – we are piloting development and deployment of Physical AI solutions. At the heart of this transformation is a groundbreaking digital twin solution for simulating Toyota forklifts in a virtual environment of warehouses and factories.

Solving real-world challenges with Physical AI

One of the important challenges in robotics is the ability to simulate real-world scenarios with high fidelity. Traditional testing methods are often slow, expensive, and limited in scope. Recognising these challenges, we collaborated with SoftServe and NVIDIA to create a virtual copy of autonomous forklifts, enabling precise simulation and analysis across diverse operational conditions in digital twins built using the NVIDIA Omniverse, a platform of APIs, SDKs, and services that enable developers to easily integrate OpenUSD and RTX rendering technologies.

This digital twin approach bridges the gap between design and deployment, empowering validation and optimisation of our robotic systems in a controlled, scalable and cost-effective environment, which enables faster Time-to-Market and higher quality.

ooking ahead: scaling innovation through strategic collaboration

As a company, we are committed to shaping the future of logistics through continuous innovation and strong partnerships.

Our focus moving forward is on expanding the scope of digital twin simulations, deepening collaboration with technology leaders like NVIDIA and SoftServe, and streamlining the path from virtual testing to real-world deployment. By investing in scalable AI models and staying attuned to emerging trends, we aim to keep a leading position in warehouse automation.